Before selecting a hinge, it’s essential to clearly define its intended function and performance requirements within the product. Once these needs are understood, you can evaluate hinge options more accurately. One of the key criteria is material selection and mechanical performance:

1. Materials & Mechanical Performance

Metal Materials

Metals such as stainless steel, carbon steel, and aluminum alloys offer excellent strength, hardness, and wear resistance. They can withstand heavy loads and frequent opening–closing cycles, making them ideal for applications that require structural durability and a long service life.

Engineering Plastics

Materials like POM (acetal) and PA (nylon) provide strong corrosion resistance, fatigue resistance, and electrical insulation. Their lightweight properties and design flexibility make them suitable for applications where aesthetics, weight reduction, and cost efficiency are important.

2. Precision & Manufacturing Quality

Dimensional Accuracy:

The dimensional precision of a hinge directly influences its motion accuracy and overall stability. Applications requiring high-precision movement or tight structural tolerances should select hinges manufactured with stricter tolerances and higher machining accuracy.

Surface Finish & Treatments:

Surface roughness affects wear resistance, friction, and overall lifespan. Treatments such as chrome plating, nickel plating, anodizing, or coating can significantly enhance corrosion resistance, Smoothness, and appearance—ultimately improving performance and durability.

3. Rotational Performance

Smooth Rotation:

A high-quality hinge should rotate smoothly with minimal resistance, ensuring stable operation, reduced noise, and lower wear. Proper lubrication—whether through grease, oil, or self-lubricating materials—can greatly improve rotational performance and extend service life.

Speed Stability:

For high-speed applications, the hinge must maintain excellent rotational stability to reduce vibration, noise, and heat generation, ensuring efficient and reliable performance.

4. Load-Bearing Capability

Torque Capacity:

Select a hinge with sufficient torque capacity based on actual operating conditions, while incorporating an appropriate safety margin to prevent fatigue, deformation, or failure under load.

Bending Stiffness:

For applications requiring the hinge to withstand lateral forces or significant bending, bending rigidity becomes crucial. High stiffness ensures that the hinge maintains structural stability and operates Smoothly without deformation.

5. Environmental Adaptability

Temperature Resistance:

Select hinge materials and lubricants that can maintain stable performance across the expected operating temperature range, whether for high-heat environments or low-temperature conditions.

Humidity Resistance:

For applications exposed to high humidity or moisture, choose hinges with strong corrosion-resistant properties or consider sealed structural designs to ensure long-term durability and performance stability.

6. Service Life and Reliability

Fatigue Life:

Choose hinge materials and manufacturing processes that offer high fatigue strength, in line with the equipment’s estimated duty cycles and lifespan requirements.

Reliability:

Opt for hinge products that have undergone proven reliability and durability testing to ensure consistent, stable performance during long-term operation.

When selecting a suitable factory, we mainly consider the following aspects:

1.Technical Capability

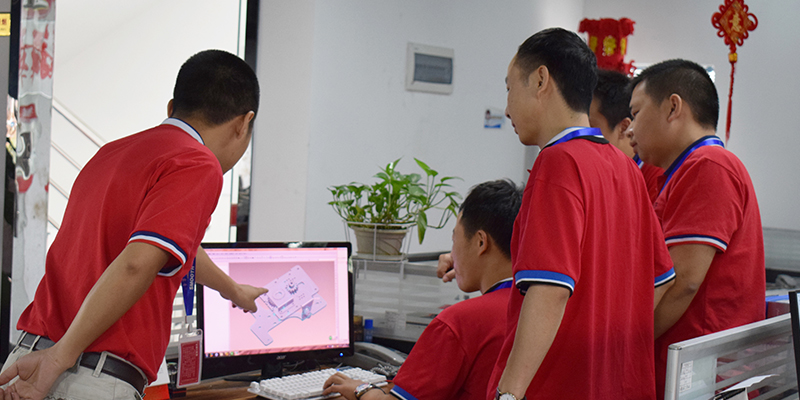

R&D Capability:

Assess whether the manufacturer has a dedicated and experienced R&D team capable of delivering customized designs and solutions tailored to your specific needs.

Technical Expertise:

Check if the factory is equipped with advanced production technologies and mature process controls to ensure that products consistently meet technical specifications and quality standards.

Innovation Capability:

Determine whether the manufacturer continuously invests in technological innovation and can introduce new products aligned with market trends—helping customers maintain a competitive edge.

2.Production Capacity & Quality Management

Production Scale:

Assess whether the factory has the necessary production capacity to handle your order volume, including peak-season output and unexpected demand spikes.

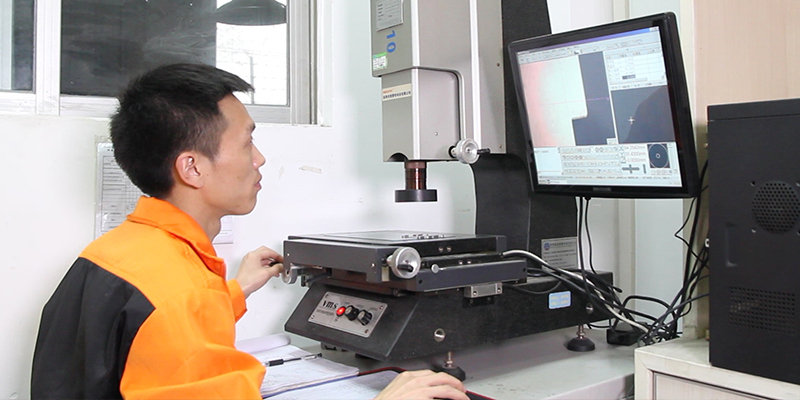

Quality Management:

Determine whether the factory has a robust quality management system in place to ensure product stability, reliability, and consistency. Check for clearly defined inspection standards, strict QC processes, advanced testing equipment, and trained quality personnel capable of conducting comprehensive product evaluations.

Process Control:

Evaluate the factory’s ability to manage production with precision—covering efficiency, yield control, and cost optimization. Consider whether they use advanced production management systems and technologies that support real-time visibility, traceability, and intelligent process control.

Environment & Safety:

Confirm that the factory holds the required environmental and safety certifications to ensure compliant, safe, and eco-friendly operations. Review whether they have established formal environmental protection measures and safety management systems to safeguard employee well-being and workplace safety.

3. Service & After-Sales Support

Pre-Sales Support:

Evaluate whether the factory can provide comprehensive pre-sales consultation and technical guidance. A capable supplier should clearly explain product features, performance details, and application scenarios while responding promptly to customer inquiries. Top-tier manufacturers also offer sample testing and validation services to ensure the product meets real-world application needs.

After-Sales Support:

Assess the completeness of the factory’s after-sales service system, including installation guidance, system calibration, repair support, and other one-stop technical services. A reliable supplier will have a dedicated service team to respond quickly and provide timely solutions. Long-term technical assistance, product maintenance, and upgrade services are key indicators of strong customer support.

Compliance With Industry Standards:

Review how well the factory understands and complies with relevant industry standards and regulations. Full compliance is essential to ensure product safety, market acceptance, and Smooth entry into global markets.

Market Reputation & Customer Feedback:

Check the factory’s track record through industry evaluations, online reviews, and feedback from existing customers. Speaking directly with users who have worked with the supplier can provide deeper insights into product quality, delivery performance, and overall service experience.

Supply Stability & Delivery Capability:

Evaluate the factory’s production scheduling, capacity planning, and on-time delivery performance. Ensuring they can consistently meet deadlines—even during peak seasons—is crucial for Smooth project execution and preventing supply chain disruptions.

Customization Capability:

Determine whether the supplier can provide customized design and manufacturing services for special requirements. Manufacturers with strong R&D and flexible engineering capabilities can deliver tailored solutions that elevate product competitiveness and meet unique customer needs.